LAG-S200 Ladle Slag Detection System Vibration Type

Overview of LAG-S200

LAG-S200 Ladle Slag Detection System Vibration Types

The meaning of the system

1. Reduce the amount of tundish slag

2. Improve the purity of molten steel

3. Improve the life of the tundish

4. Reduce sliding nozzle erosion

5. Reduce nozzle blockage

6. Increase continuous pouring heats

7. Improve the yield of molten steel

8. Improve the quality of continuous casting billets

The continuous casting vibration type ladle slag detection device

The continuous casting vibration type ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of vibration detection.

The LAG-S200 continuous casting ladle slag automatic detection system is developed by Wuhan CenterRise M&C Engineering Co., Ltd. after many years of research with many scientific research institutes, and fully combined with the actual situation on site. It has a real field application value as a continuous casting ladle slag automatic detection system.

The working principle of LAG-S200 continuous casting ladle slag automatic monitoring system

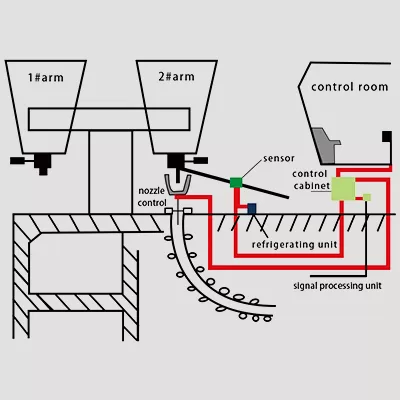

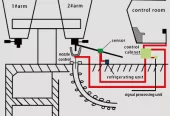

The LAG-S200 continuous casting ladle slag automatic monitoring system detects the slag state during the pouring process by receiving the vibration signal of the mechanical operating arm of the ladle nozzle. In the process of molten steel pouring, when molten steel flows through the long nozzle and pours into the tundish, the molten steel impacts the wall of the long nozzle and causes the vibration of the mechanical operating arm used to support the long nozzle. Since the specific gravity of the steelmaking slag is less than half of the specific gravity of the molten steel, it floats on the surface of the molten steel, and the steelmaking slag appears when the molten steel is about to be all poured.

The system mainly monitors the ladle slag of the continuous casting by measuring and analyzing the vibration difference of the mechanical operating arm.

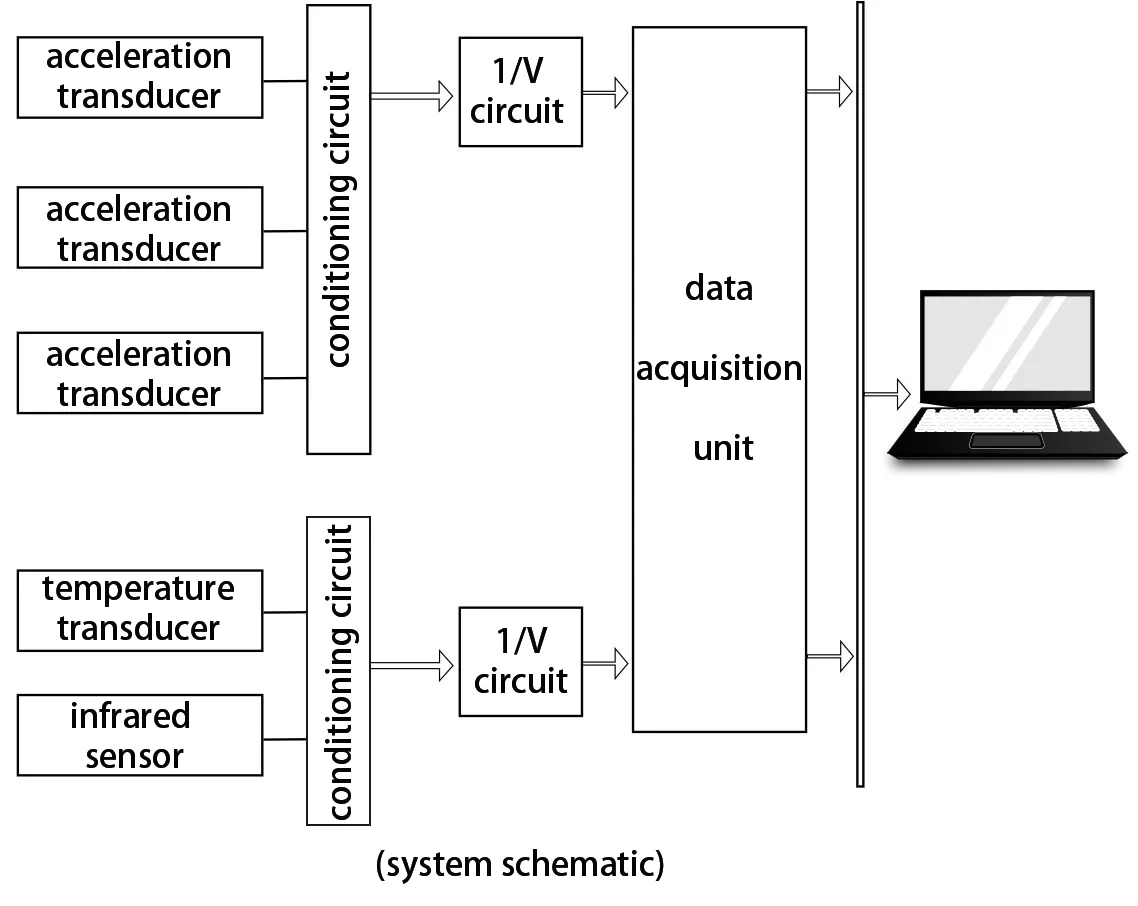

The vibration signal is connected to the operation control unit of the system control cabinet through the front-stage conditioning and amplification module through the sensor installed in the middle of the operating rod. After processing, it is output to the industrial computer for operation and analysis.

The features of LAG-S200 system

(1) It is easy to install, basically no modification is made to the field equipment, and the installation and debugging work will not affect the normal production of the enterprise.

(2) The detection accuracy is high, and the effective rate is greater than or equal to 95%.

(3) The sensor is installed at a position far away from the molten steel, and is cooled by a special refrigeration device for 24 hours. The outer layer adopts a composite protection structure, which has a long service life.

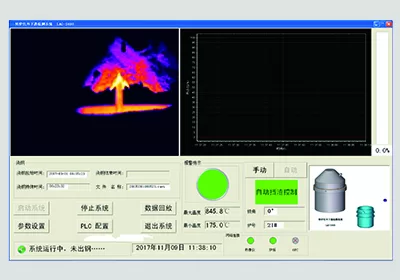

(4) Adopt professional and targeted signal processing methods to obtain the vibration characteristic parameters of the ladle slag, and analyze, reason and judge the effective slag signal through the vibration signal database, which has a high accuracy of slag alarm.

(5) The equipment adopts a modular design.

(6) The system has a powerful database function.

(7) The system has the function of automatically controlling the ladle nozzle.

The composition of LAG-S200 system

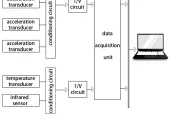

The LAG-S200 slag detection system consists of: vibration detection sensor, pre-signal amplifier, slag detection operation unit, tundish liquid level control unit, on-site operation indication box, and process control cabinet.

1. Vibration detection sensor: It is installed on the robotic arm of the stopper to detect the vibration signal of the whole casting process of the ladle.

2. Pre-signal amplifier: Amplify, convert and transmit the weak vibration signal detected by the vibration detection sensor.

3. Slag detection operation unit: Analyze, judge and discriminate the vibration signal to realize the discrimination of all steel, mixed slag and full slag , and output the slag alarm signal.

4. On-site operation instruction box: Provides man-machine exchange for slag alarm indication, fault indication, system activation mode selection, and control mode selection.

5. Process control cabinet, providing power management, displaying man-machine interface and setting management.

The parameters of the system

1. The system controls the slag inclusion in molten steel with high precision and closes the nozzle in real time.

2. Improve the quality of steel, reduce defective products, and improve the yield.

2. Reduce the blockage of the tundish nozzle and increase the number of continuous pouring heats of the tundish.

Leave feedback about this